Speciality Metals

Tin

Mostly used in the electronics industry, it is an indispensable component in every circuit board, battery pack and wireless connectivity device. However, its uses span such a vast array of applications it is one of the most important elements in modern living.

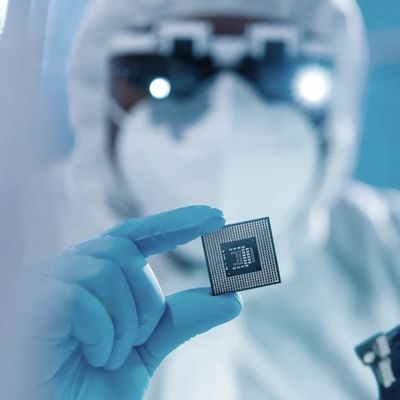

Tantalum

Tantalum is best known for its use in electronics where its unique properties make it a leading choice in capacitor manufacturing, surface acoustic wave filters and use in sputtering targets for the semi-conductor industry.

The three global mega-trends driving demand: the 5G roll out; Internet of Things; and the green energy transition; are putting unprecedented pressure on suppliers to add significant increases to capacity.

Niobium

Whilst also utilised in the electronics industry, the largest use of niobium is in high-grade structural steel and super alloys.

It is an indispensable component in high-technology applications such as MRIs, jet engine's, medical implants, and a multitude of other specialist areas which require the unique properties of a high-entropy alloy.

Sales Inquiries

Copyright © 2024 POWER RESOURCES INTERNATIONAL LTD - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.